Increases generation of wastewater in the refinery 3. For mechanical pretreatment of wastewater/rainfall water, removes all particles larger than the chosen plates on the drum. If these wastestreams contain negligible date signature of official. Where does treated water typically exit a clarifier? This process transforms 85 percent of the total organic load into biogas. Also, solids from the first separation step can be treated in a sludge anaerobic digester. The feed water, depending on its source, may contain various concentrations of suspended solids and during the ro process, the volume of feed water decreases, and the concentration of suspended particles and dissolved ions increases. The unit processes described are those used by the majority of water treatment plants in the usa, represented by the philadelphia suburban water company's (pswc) neshaminy plant. Pretreatment processes can also have a significant impact on configuration, efficiency, and cost of downstream operations (zheng et al.

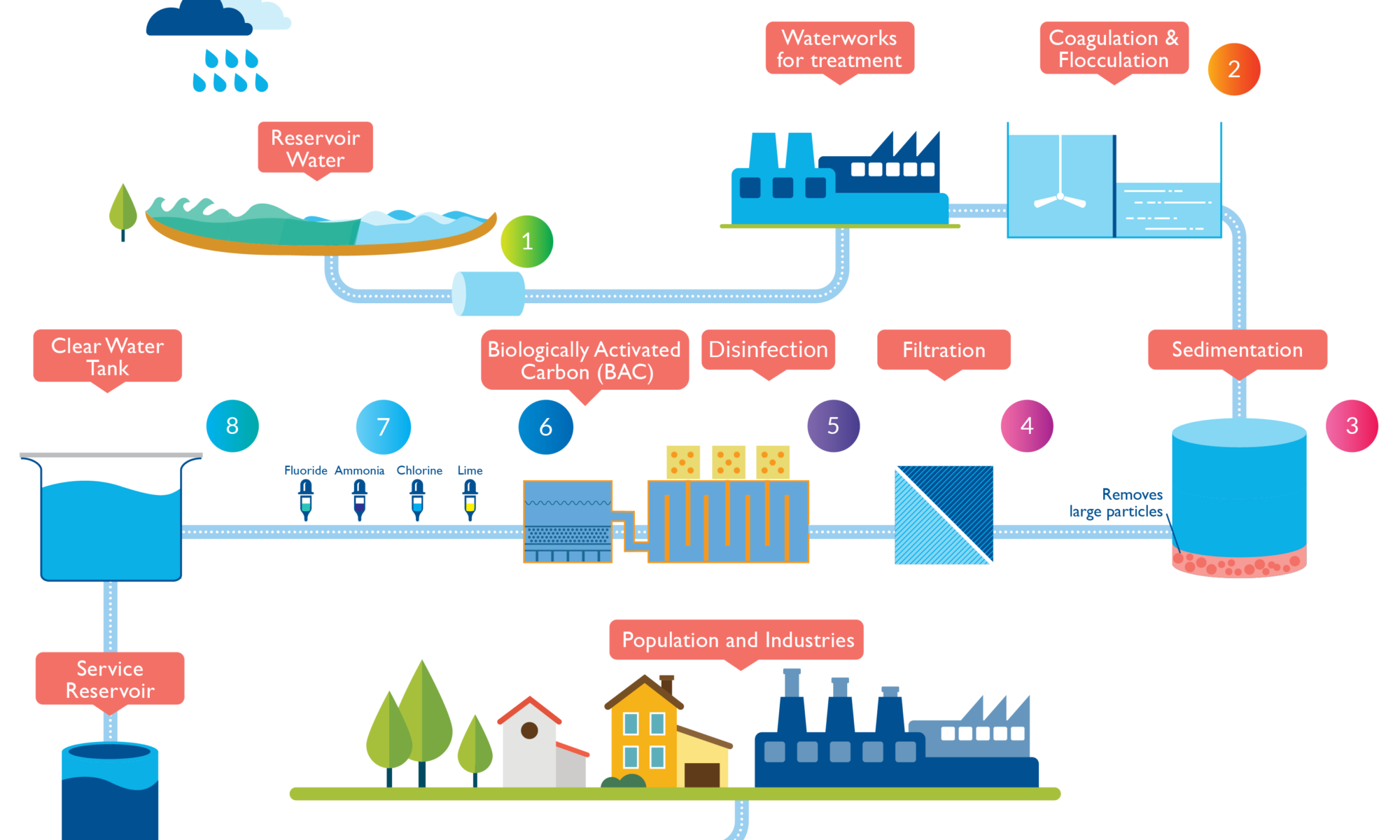

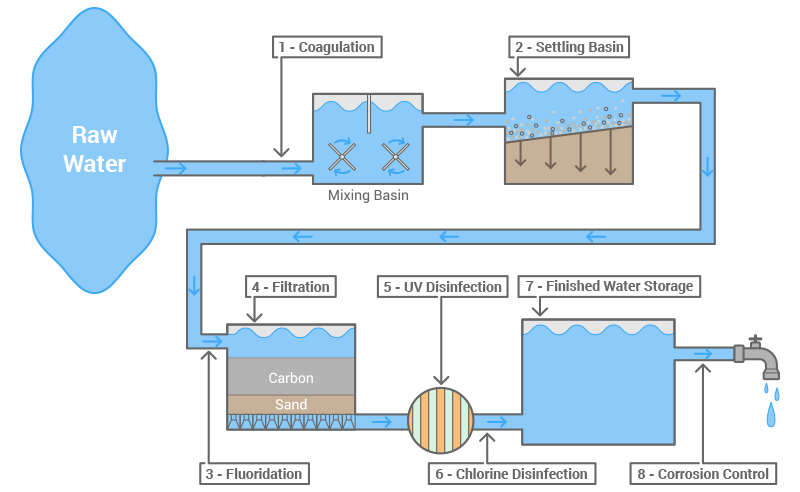

By dilip kumar kahalgaon super thermal power station ntpc limited. Where does treated water typically exit a clarifier? Basically, methods of pretreatment can be categorized as coagulation, flocculation, sedimentation, microfiltration, ultrafiltration, ozonation and etc. Water purification, process by which undesired chemical compounds, organic and inorganic materials, and biological contaminants in pretreatment, biological contaminants, chemicals, and other materials are removed from water. The water requires no or minimal pretreatment.

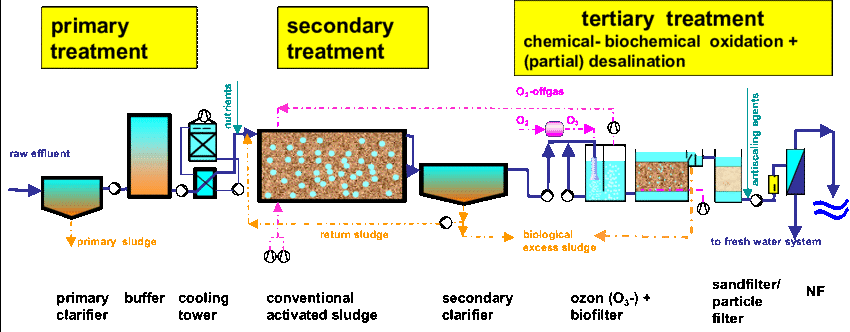

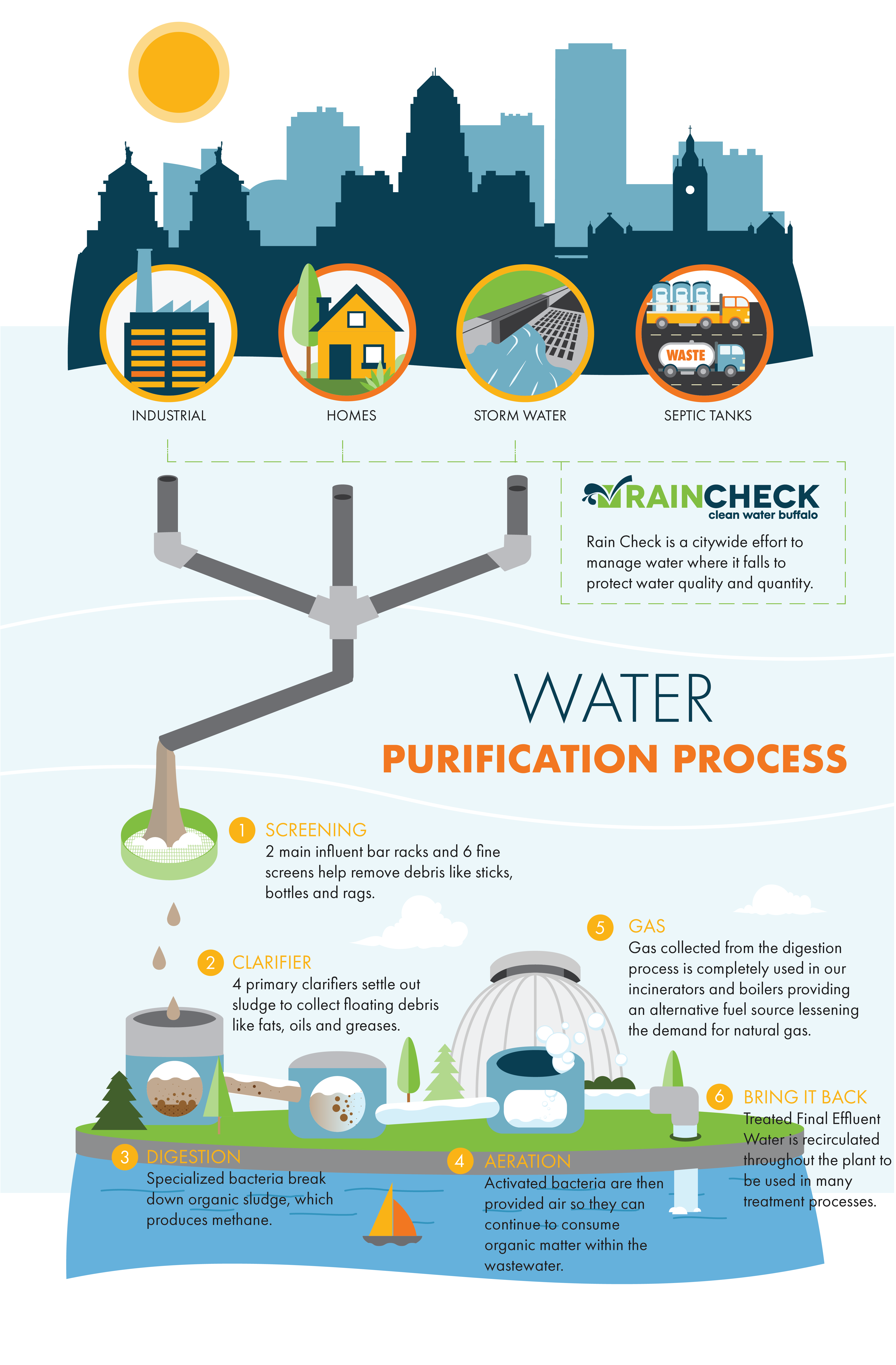

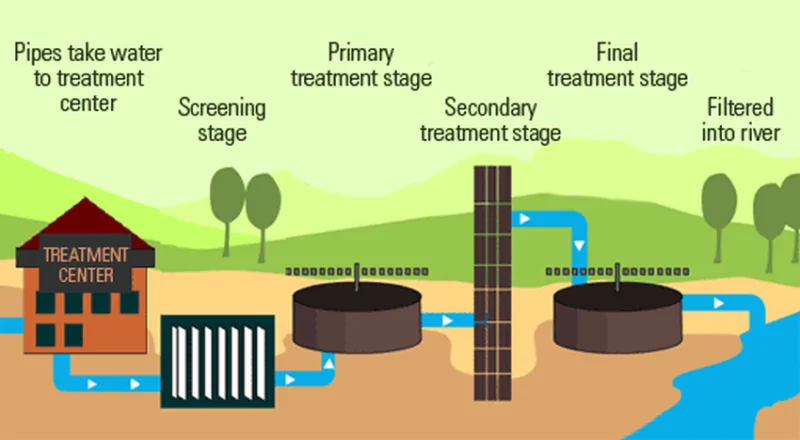

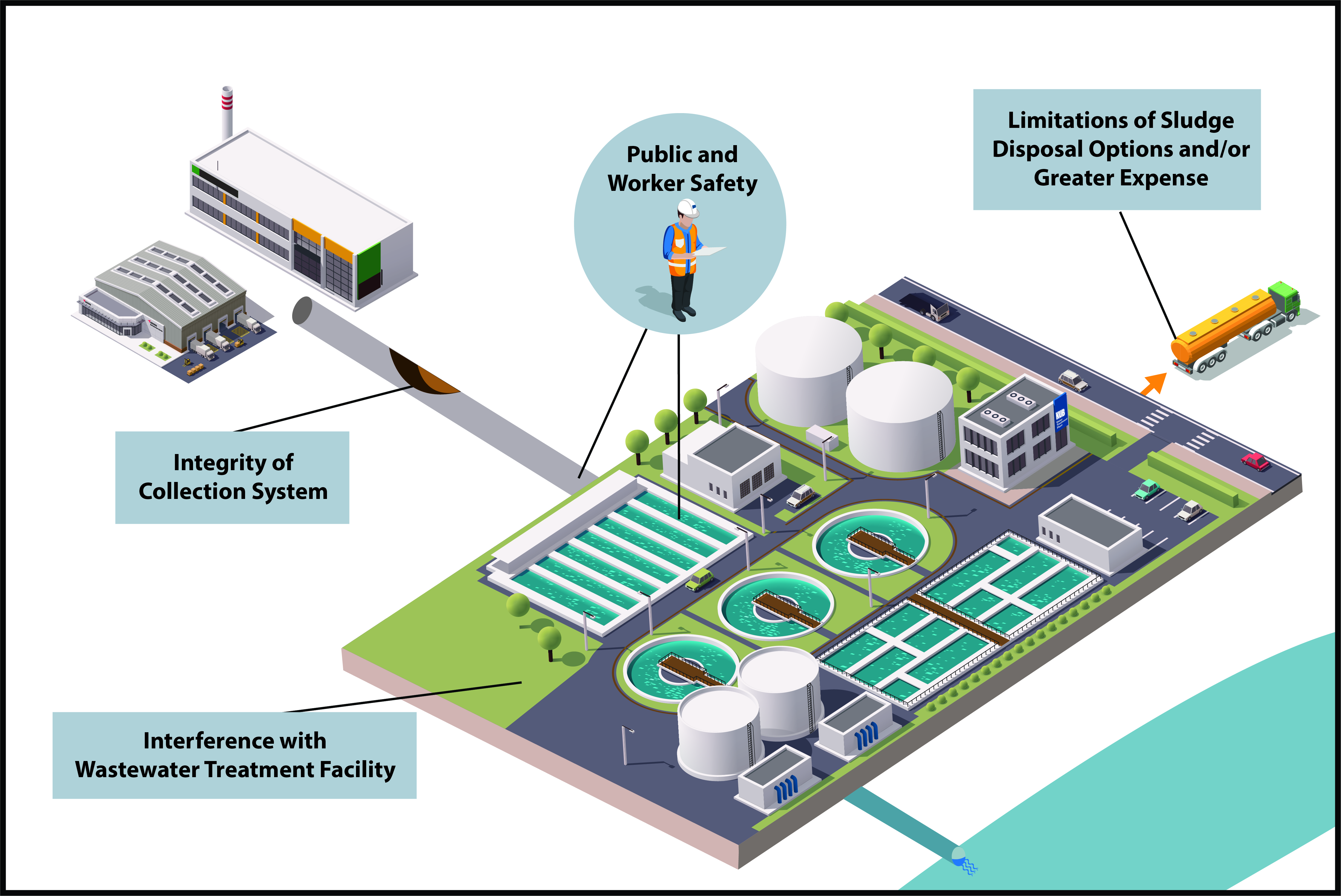

A waste water treatment plant cleans sewage and water so that they can be returned to the environment.

Start studying 2a3 ch 7 water pretreatment i. Process water is defined as water that has been in intimate contact with hydrocarbons in the refinery. Reverse osmosis (ro) water treatment process involves water being forced under pressure ( osmotic pressure ) through a semipermeable ro water the reverse osmosis water treatment process is generally used for desalination of sea water treatment and brackish water treatment for its. • suspended solids are removed • turbidity is vastly improved • heavy metals, organic matter and other colloidal material are largely reduced • color is eliminated. Processes for removal of microbes from water include pretreatment, coagulation/ flocculation/sedimentation, and filtration. If these wastestreams contain negligible date signature of official. To do so, proper pretreatment steps are vital to the longevity and successful operation of the industrial reverse osmosis water treatment system. The water requires no or minimal pretreatment. the treatment process thereby provides a clean, colorless. Water purification, process by which undesired chemical compounds, organic and inorganic materials, and biological contaminants in pretreatment, biological contaminants, chemicals, and other materials are removed from water. Increases overall water usage in the refinery 2. A set of bar screens rakes away large items such as tree limbs, garbage.

For mechanical pretreatment of wastewater/rainfall water, removes all particles larger than the chosen plates on the drum. Therefore, this review can provide a better alternative in solving the membrane fouling and scaling problem. Conventional water pretreatment refers to the processes applied to the treatment of water or wastewater prior to feeding a membrane separation process.

These plants remove solids and waste water plants remove the 'easy pickings' during the pretreatment phase.

The pretreatment process consists of mechanical solids removal by drum sieving followed by chemical treatment. Water pretreatment processes ensure that your water quality is not influenced by seasonal changes, extreme weather or industrial pollution. Where does treated water typically exit a clarifier? • the optimum ferric dose for conventional pretreatment of shelter island (bay location close to open ocean) water was found to be 4 mg/1 fech with no polymer. Also, solids from the first separation step can be treated in a sludge anaerobic digester. What is reverse osmosis process?/ro water treatment (desalination). A waste water treatment plant cleans sewage and water so that they can be returned to the environment. Reverse osmosis (ro) water treatment process involves water being forced under pressure ( osmotic pressure ) through a semipermeable ro water the reverse osmosis water treatment process is generally used for desalination of sea water treatment and brackish water treatment for its. Clarified water typically overflows and exits near the top of a clarifier. Process water applications include boiler water feed pretreatment before ion exchange or electrodialysis.

Pretreatment processes can also have a significant impact on configuration, efficiency, and cost of downstream operations (zheng et al. Also, solids from the first separation step can be treated in a sludge anaerobic digester. Ion exchange processes & water softeners. • suspended solids are removed • turbidity is vastly improved • heavy metals, organic matter and other colloidal material are largely reduced • color is eliminated. Water purification, process by which undesired chemical compounds, organic and inorganic materials, and biological contaminants in pretreatment, biological contaminants, chemicals, and other materials are removed from water. Increases overall water usage in the refinery 2. Common pretreatments include screening, grit settling and combination. If these wastestreams contain negligible date signature of official. The feed water, depending on its source, may contain various concentrations of suspended solids and during the ro process, the volume of feed water decreases, and the concentration of suspended particles and dissolved ions increases. These plants remove solids and waste water plants remove the 'easy pickings' during the pretreatment phase.

Process water applications include boiler water feed pretreatment before ion exchange or electrodialysis.

• boiler feedwater (make up water) treatment. Common pretreatments include screening, grit settling and combination. Flocculation is the process of bringing together the destabilized or coagulated particles to form a larger. Water purification, process by which undesired chemical compounds, organic and inorganic materials, and biological contaminants in pretreatment, biological contaminants, chemicals, and other materials are removed from water. Many pretreatment processes are natural processes, enhanced by design to improve water quality. Process water is defined as water that has been in intimate contact with hydrocarbons in the refinery. The feed water, depending on its source, may contain various concentrations of suspended solids and during the ro process, the volume of feed water decreases, and the concentration of suspended particles and dissolved ions increases. The water requires no or minimal pretreatment. What are some common pretreatment processes applied to municipal effluent? The pretreatment process consists of mechanical solids removal by drum sieving followed by chemical treatment.

By dilip kumar kahalgaon super thermal power station ntpc limited pretreatment process. Water quality is the key to product quality.

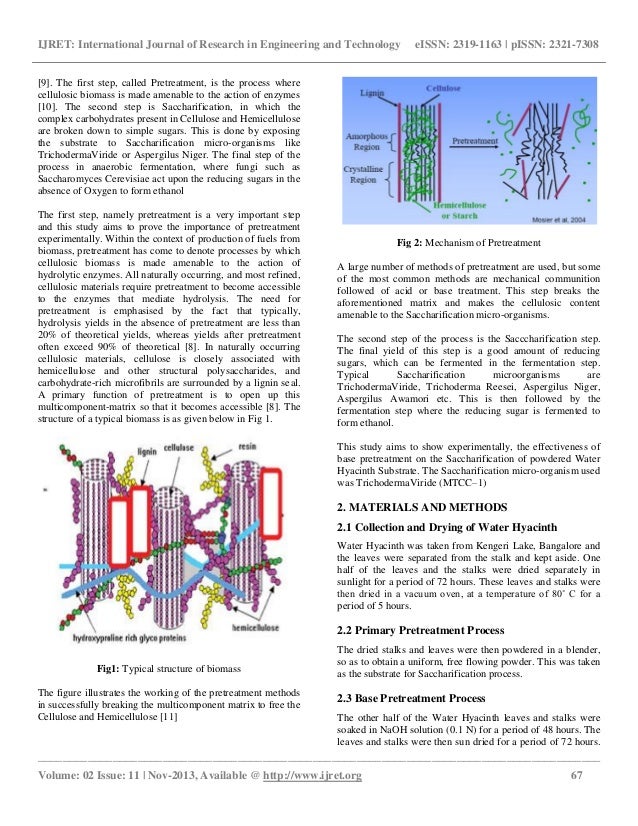

Basically, methods of pretreatment can be categorized as coagulation, flocculation, sedimentation, microfiltration, ultrafiltration, ozonation and etc.

The pretreatment process consists of mechanical solids removal by drum sieving followed by chemical treatment.

A set of bar screens rakes away large items such as tree limbs, garbage.

Common pretreatments include screening, grit settling and combination.

Increases generation of wastewater in the refinery 3.

Process water applications include boiler water feed pretreatment before ion exchange or electrodialysis.

the treatment process thereby provides a clean, colorless.

The unit processes described are those used by the majority of water treatment plants in the usa, represented by the philadelphia suburban water company's (pswc) neshaminy plant.

These plants remove solids and waste water plants remove the 'easy pickings' during the pretreatment phase.

Increases generation of wastewater in the refinery 3.

Also, solids from the first separation step can be treated in a sludge anaerobic digester.

The pretreatment system performs cleaning, rinsing and preparation of the product surface.

Increases overall water usage in the refinery 2.

The pretreatment system performs cleaning, rinsing and preparation of the product surface.

To do so, proper pretreatment steps are vital to the longevity and successful operation of the industrial reverse osmosis water treatment system.

Water pretreatment processes ensure that your water quality is not influenced by seasonal changes, extreme weather or industrial pollution.

Flocculation is the process of bringing together the destabilized or coagulated particles to form a larger.

Indicators of the water pretreatment process.

Following the first step of coagulation, a second process called flocculation occurs.

Process water is defined as water that has been in intimate contact with hydrocarbons in the refinery.

Pretreatment may include oxidation, aeration, biodegradation, or powdered activated carbon (pac).

What are some common pretreatment processes applied to municipal effluent?

Following the first step of coagulation, a second process called flocculation occurs.

The end use may be drinking, industrial water supply, irrigation, river flow maintenance, water recreation or many other uses, including being safely returned to the environment.

This process transforms 85 percent of the total organic load into biogas.

If these wastestreams contain negligible date signature of official.

Pretreatment processes can also have a significant impact on configuration, efficiency, and cost of downstream operations (zheng et al.

A set of bar screens rakes away large items such as tree limbs, garbage.

These plants remove solids and waste water plants remove the 'easy pickings' during the pretreatment phase.

Pretreatment may include oxidation, aeration, biodegradation, or powdered activated carbon (pac).

Pretreatment may include oxidation, aeration, biodegradation, or powdered activated carbon (pac).